Perforated Sheet Metal Products: How We Make Them and Why You Need Them

How do we make perforated sheet metal products? And why should you choose us as your contract manufacturing partner in Vietnam? In this article, we will answer these questions and show you how we can provide you with high-quality perforated sheet metal products using our advanced technologies and techniques.

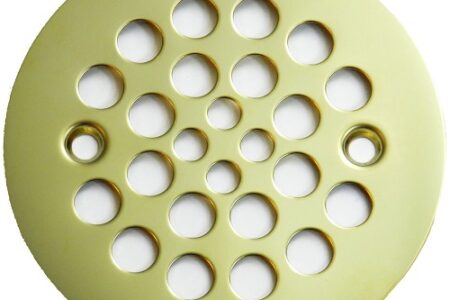

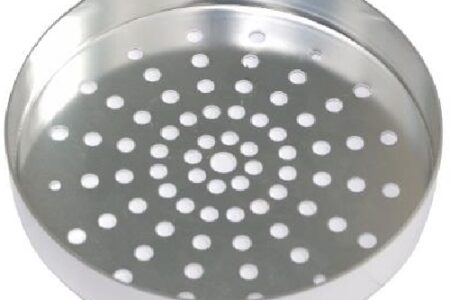

Perforated sheet metal products are metal sheets that have been punched with holes, slots, or other patterns to create various shapes and designs. Perforated sheet metal products are widely used in various industries and applications, such as architecture, engineering, construction, agriculture, automotive, and more. Perforated sheet metal products can offer many benefits, such as ventilation, filtration, sound absorption, light diffusion, aesthetic appeal, and weight reduction.

How We Make Perforated Sheet Metal Products

We are a foreign owned contract manufacturing factory in Vietnam that specializes in perforated sheet metal products. We have a team of skilled and experienced sheet metal fabricators, who can handle any perforated sheet metal project, from simple to complex, with precision and efficiency. We also have a fleet of state-of-the-art machines, which can perform various processes, such as laser cutting, CNC turret punching, and TIG or MIG welding. Here is a brief overview of each process:

– Laser cutting: Laser cutting is a process of cutting sheet metal using a high-powered laser beam. Laser cutting is fast, accurate, and versatile. It can cut any shape and size of sheet metal, with minimal waste and distortion. Laser cutting is ideal for creating intricate and detailed designs, such as logos, patterns, and holes. We use both fiber and CO2 laser cutting machines, which can cut various alloys up to 20mm thickness.

– CNC turret punching: CNC turret punching is a process of punching sheet metal using a computer-controlled machine. CNC turret punching is strong, durable, and easy. It can punch any shape and size of sheet metal, with high speed and consistency. CNC turret punching is suitable for creating simple and regular shapes, such as round holes, slots, and squares. We use CNC turret punching machines, which can punch various materials up to 6mm thickness.

– TIG or MIG welding: TIG or MIG welding is a process of joining sheet metal parts together using heat and pressure. TIG or MIG welding is solid, permanent, and flexible. It can join sheet metal parts of similar or dissimilar metals, with or without filler material. TIG or MIG welding is useful for creating seamless and smooth joints, such as corners, edges, and curves. We use TIG or MIG welding machines, which can weld various materials up to 20mm thickness.

We can combine these processes to create perforated sheet metal products that meet your specifications and requirements. We can also provide additional services, such as bending, tapping, deburring, graining, and powder coating, to give your perforated sheet metal products a perfect finish.