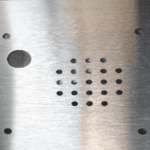

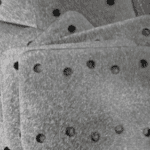

What are burrs and why do they need to be removed?

Burrs are small, unwanted pieces of metal that are formed when metal is cut, stamped, drilled, or machined. Burrs can cause several problems, such as:

- Reducing the accuracy and functionality of the metal parts

- Interfering with the assembly and fitting of the metal parts

- Damaging the tools and equipment that handle the metal parts

- Creating safety hazards for the workers and the end-users of the metal parts

- Affecting the aesthetic and visual appeal of the metal parts

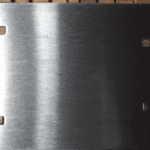

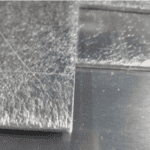

What is hairline finishing and why is it important?

Hairline finishing is a type of surface finishing that creates a smooth and uniform appearance on the metal parts. Hairline finishing is also known as satin finishing, brushed finishing, or directional finishing, because it produces fine, parallel lines on the metal surface. Hairline finishing is important because it:

- Enhances the aesthetic and visual appeal of the metal parts

- Improves the corrosion and wear resistance of the metal parts

- Reduces the friction and noise of the metal parts

- Facilitates the cleaning and maintenance of the metal parts

Hairline finishing can be done using various methods, such as:

- Deburring machines: These machines use abrasive belts, brushes, or discs to create a hairline finish on the metal parts

- Manual polishing: This method uses a hand-held tool, such as a sander or a grinder, to create a hairline finish on the metal parts

- Chemical polishing: This method uses a chemical solution, such as an acid or a base, to create a hairline finish on the metal parts

Why choose us for your deburring and hairline finishing needs?

We are a trusted and experienced company that can provide deburring services and hairline finishing of sheet metal products for various industries, such as:

- Automotive

- Aerospace

- Medical

- Construction

- Furniture

- And more

We have a team of skilled and qualified technicians who can handle any type of metal, such as:

- Steel

- Stainless steel

- Aluminum

- Copper

- Brass

- And more

We have a range of modern and efficient machines that can perform deburring and hairline finishing of sheet metal products with precision and speed. We can also customize our services to meet your specific requirements and specifications. We offer competitive prices and fast turnaround times for our deburring and hairline finishing services. We guarantee your satisfaction and quality assurance for every project we undertake.