Here is a brief overview of each process:

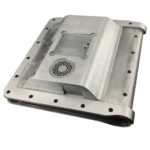

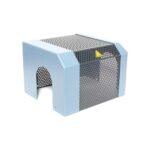

- CNC turret punching: CNC turret punching is a process of punching sheet metal using a computer-controlled machine. CNC turret punching is strong, durable, and easy. It can punch any shape and size of sheet metal, with high speed and consistency. CNC turret punching is suitable for creating simple and regular shapes, such as round holes, slots, and squares. We use CNC turret punching machines, which can punch various materials up to 6mm thickness.

- Laser cutting: Laser cutting is a process of cutting sheet metal using a high-powered laser beam. Laser cutting is fast, accurate, and versatile. It can cut any shape and size of sheet metal, with minimal waste and distortion. Laser cutting is ideal for creating intricate and detailed designs, such as logos, patterns, and holes. We use both fiber and CO2 laser cutting machines, which can cut various alloys up to 20mm thickness.

- CNC bending: CNC bending is a process of bending sheet metal using computer-controlled machines. CNC bending is precise, consistent, and adaptable. It can bend sheet metal into any angle and shape, with high accuracy and repeatability. CNC bending is helpful for creating complex and custom shapes, such as brackets, hooks, and tubes.

- MIG and TIG welding: MIG and TIG welding are processes of joining sheet metal parts together using heat and pressure. MIG and TIG welding are solid, permanent, and flexible. They can join sheet metal parts of similar or dissimilar metals, with or without filler material. MIG and TIG welding are useful for creating seamless and smooth joints, such as corners, edges, and curves. We use MIG and TIG welding machines, which can weld various materials up to 20mm thickness.

We can combine these processes to create sheet metal products that meet your specifications and requirements. We can also provide additional services, such as tapping, deburring, graining, and powder coating, to give your sheet metal products a perfect finish.

We work with a wide range of metal materials, such as steel, stainless steel, aluminum, copper, brass and galvanized steel. We also offer optional surface treatments, such as:

- Tapping: Tapping is a process of creating threads on sheet metal parts using a special tool. Tapping is strong, secure, and easy. It can create threads on sheet metal parts of different thicknesses, materials, and shapes, without the need for drilling or welding. Tapping is useful for attaching sheet metal parts to other components, such as screws, nuts, and bolts.

- Deburring: Deburring is a process of removing sharp edges and burrs from sheet metal parts using a machine or a tool. Deburring is smooth, safe, and clean. It can remove any unwanted material from sheet metal parts, with minimal damage and dust. Deburring is important for improving the appearance and performance of sheet metal parts, as well as preventing injuries and defects.

- Graining: Graining is a process of creating a uniform and fine surface on sheet metal parts using a machine or a tool. Graining is aesthetic, durable, and resistant. It can create a smooth and shiny surface on sheet metal parts, with enhanced corrosion and scratch resistance. Graining is beneficial for adding value and beauty to sheet metal parts, as well as protecting them from wear and tear.

- Powder coating: Powder coating is a process of applying a dry and colored powder on sheet metal parts using an electrostatic spray gun. Powder coating is colorful, protective, and eco-friendly. It can apply any color and finish on sheet metal parts, with high quality and durability. Powder coating is advantageous for giving sheet metal parts a custom and attractive look, as well as shielding them from rust and fading.

We are committed to delivering high-quality sheet metal fabrication services at competitive prices and fast turnaround times. We offer you instant online quotes and online ordering, as well as design for manufacturability feedback and ISO 9001 certified quality assurance. We help you with innovative and customized solutions for your sheet metal fabrication needs.

Contact us today and get your online quote for sheet metal products for machines and devices. We are your contract manufacturing partner in Vietnam that can offer you the best sheet metal fabrication services.

More information about sheet metal can be found on Wikipedia